TA-8960 MON: Supporting Agriculture Value Chain

TA-MON8960 Supporting Agriculture Value Chain Project is providing technical assistance to the current Agriculture and Rural Development Project – Additional Financing (Loan 3287/88-MON). Therefore, the Consultant is closely linked to the Value Chain Investment team for output 1 of the project with the guidance of ADB project officer and supervision of the Project director and PIU coordinator.

Monconsult Ltd in association with Agri Consulting Europe SA (AESA), Belgium and Landell Mills Limited (LML), United Kingdom (Here in after referred to as the Consultant) was contracted by Asian Development Bank (ADB) to undertake a Technical Assistance (TA) for Supporting Agriculture Value Chain.

The Technical Assistance (TA) Team started its operation on 21 March 2017 and fully been mobilized by 10 May 2017. The TA Team consists of eight (8) national experts and five (5) International experts. Due to the COVID impact on smooth implementation of the TA activities the duration has been extended with no-cost condition till June30, 2021.

The MOFALI is the Implementing Agency for the TA Project. Due to the nature of the various sub-sectors involved in the project, the two Technical Advisory Units (TAU) have been established separately by the Order of State Secretary of the MOFALI on May 2017. A total of 10 TAU meetings were held which provided detailed recommendations and solutions.

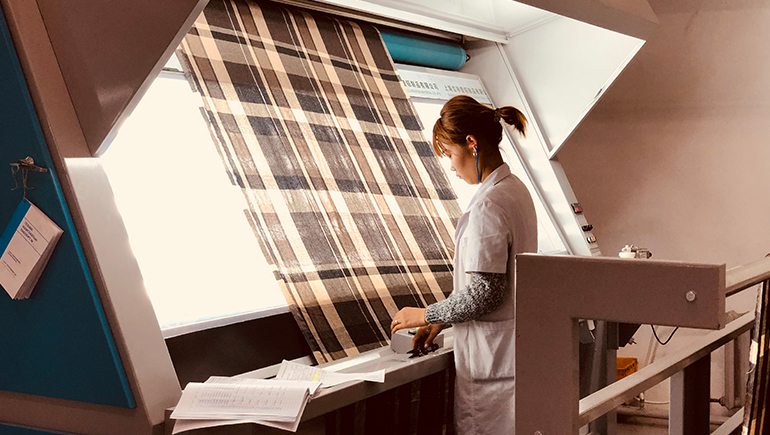

The project covers seven (7) subsectors namely fiber, garment, leather/footwear, sea buckthorn, bee-farming, meat and dairy. Since the TA implementation a total of 181 trainings were delivered under Outputs 2, 3 and 4, involving 7,011 participants.

Project results:

- More specifically, 76 trainings are organized for 3,881 herders and farmers (52.1% are women) and 96 class room and on-the job trainings were conducted that involved 3130 person-times of PPEs and other enterprises (of which 74.5% are women).

- The technical specifications of 105 types of equipment had been developed to be supplied to research institutes, laboratories, training centers, herders, cooperatives and bee-keepers. The trial on manufacturing school footwear from yak hide and goat skin has been successfully completed.

- School footwear proto-types were produced (8 types of design for children aged 6-18). Trial for mass production testing was completed producing 110 pairs of shoes.

- Major training manuals and guidelines (23) and training-videos (7) have been developed for suppliers and producers to increase the effectiveness particularly on qualification of cashmere, yak wool, sheep and camel wool.

- Two demonstration projects for the fibre sector were identified and initiated for Blue Yak and White cashmere. Throughout the project it has been possible, through links with user groups and herders in two aimags, to develop two sustainable fiber sources which generate better yields for the PPEs.

- A total of 16 national standards, including technical requirements have been developed by TA project support of which 13 have been officially approved as MNS standards.

- In addition, 29 research studies, surveys and trials are completed under the TA Project in cooperation with selected research institutes and service providers.

- The efforts to introduce appropriate international standards based on the needs of the companies involved have achieved good results that could demonstrate the quality of Mongolian products to international buyers. More specifically, four (4) enterprises have received ISO 2009:2015, and two 2 enterprises (sea buckthorn) obtained GLOBAL G.A.P certification; also certified 2 PPEs (leather processing and shoemaking) with ISO Quality Management Standard and two PPEs have also been qualified for ISO 22000.